Flamma retardant masterbatch: enhancing polymer salutem in tutius mundo

2025-06-23

Et pervasive usum Polymers per innumerabiles industries - ex constructione et electronics ad Books et textiles - est reversed modern vitae. Tamen, inhaerens flammability multis polymeric materiae opposuit a significant salutem spectat. Hoc est ubi Flamma retardant masterbatch Partes in discrimine partes, offering efficient et effective solution augendae ignis salus plastic products.

Quid est flamma retardant masterbatch?

Flamma retardant masterbatch est concentrata mixturam flammam retardant additives encapsulated in polymer carrier resinam. Instead of directe addendo puluerem flamma retardant, quae potest ducere tractantem exitibus, pauper dispersionem, et sanitas discrimina, masterbatibatibus providebit quoddam, pulveris, et altus in formam ad incorporandam, et in Polymers in dispensando.

Et carrier resinam est typically compatible cum ultima polymer esse processionaliter, ensuring praeclara dispersionem et obscuratis aliqua negativa impulsum in Polymer scriptor mechanica proprietatibus aut dispensando mores.

Quid usus flamma retardant masterbatch?

Et commoda usura flamma retardant masterbatches super tersus flamma retardant pulveres sunt numerosis et significant:

- Improved dispersionem: Masterbatches curare homogenea distributio flammae retardants per Polymer Matrix, ducens ad consistent ignis perficientur et ne localized "calidum maculis" pauperes praesidium.

- Enhanced Processing Efficens: Sunt facile ad tractamus, influere bene, et potest esse verius dosed, ducens ad magis efficient vestibulum processus et reducitur productio costs.

- Reducitur pulvis et salus periculis: Eliminating Airborne Powder reducit periculum respiratorii exitibus ad operarios et minimizes contaminationem in productio environment.

- Consistent quale: Praecise Metering Masterbatch ensures consistent flamma retardant campester in omnibus batch, pacto certa productum perficientur.

- Minimized materia tractantem damna: Minus vastum debitum ad Pullige aut incomplete transitum comparari ad pulverem.

- Cleaner Operations: Reducitur opus crebris Purgato dispensando apparatu.

Mechanisms in flamma retardancy

Flamma retardants munus per varia machinationes inhibere vel mora ignitionem et flamma propagationem. Haec machinationes potest esse late geno:

- Corporatio: Inertes inertes dimisit per aliquando flammam retardants (E.G., NITROGENIUM, Carbon Dioxide ex intumescent systems) Dilecto flammabiles in flamma zona, elevatio ad minimum oxygeni concentration requiritur ad combustionem.

- Chemical actio in Gas phase: Quidam Flamma Retardant Release radicalis (E.G., halogen, quibus componit), quod intermixti cum libero radicalis torquem reactiones occurrenti in Gas tempus durante combustione, efficaciter "extinguitur" flamma.

- Donec actio in Condensed Phase :

- Charmata formation: Quidam flamma retardants promovere formationem firmum, non-combustable rot iacuit in Polymer superficiem. Huiusmodi agat in obice, isolating in unburnt polymer a calore et oxygeni et inhibentes effugium flammabiles volatile products. Intumescent systems sunt primam exemplum.

- EndotherMIC Demomposition: Quidam flamma retardants decepo endothermically (absorbuit calidum), cum expositae ad ignem, ita refrigerationem Polymer et dilationem eius corrumpitur. Aluminium hydroxide (Ath) et magnesium hydroxide (MDH) sunt communia exempla.

Genera Flammae retardant additives in masterbatches

Flamma retardant masterbatbatches potest incorporate amplis flammae retardant chemistries, se cum suis commoda et apta applications:

-

Halogenated flamma retardants (brominated et chlorinated):

- Mechanism: Praesertim Gas, tempus radicalis scavengers.

- Exempla: Decabromodiphenylen ethane (dbdpe), brominated epoxy oligomers, chlorinated paraffins.

- Pros: Maxime agentibus ad humilis loading levels.

- Cons: Environmental de potentiale ad PBT (pertinaciter, bioaccumulative, toxicus) substantiae et generatio mordax et toxicus fumus per combustionem. Regulatory pressuras duci ad declines in usu in multis applications.

-

Phosphoro-fundatur flamma retardants:

- Mechanism: PRIMO Condensed-tempus ratum formation. Quidam etiam exhibent Gas, tempus actio.

- Exempla: Rubrum phosphoro, Ammonium polyphosphate (app), organophosphates (E.G .: Triphenyl PHOSPHATE, Resorcinol bis (Diphenyl PHOSPHATE).)

- Pros: Saepe providere bonum Charring capabilities, environmentally amuplier quam halogenated alternatives.

- Cons: Quidam potest esse susceptibilis ad hydrolysis, et quaedam genera potest habere migrationem exitibus. Rubrum phosphoro requirit diligenter tractantem propter reactivity.

-

Hydroxides inorganicis (Mineralis Flamma Retardants):

- Mechanism: Medium Dimomprosic et DIFFERTREMMMOS DIRCUS. Et quoque release aqua vapor, Diluting flammabiles vapores.

- Exempla: Aluminium trlihydroxide (Ath) Magnesium dihydroxide (MDH).

- Pros: Non-halogenated, humilis fumus productio, cost-effective.

- Cons: Requirere valde altum loading levels (Saepe> L%) esse effective, quae non negative impulsum mechanica proprietatibus et dispensando.

-

NITROGENIUM-fundatur flamma retardants (melamine derivationes):

- Mechanism: Gas-phase MIXTURA (releasing NITROGENIUM) et promotionem charitatis in condensatione tempus.

- Exempla: Melamine Cyaanurate, melamine polyphosphate.

- Pros: Non-halogenated, bonum pro certo polymers, synergize bene cum aliis flamma retardants.

- Cons: Potest habere limitatum efficaciam in sua in aliquo polymers.

-

Silicon-fundatur flamma retardants:

- Mechanism: Promovere formationem Ceramic, sicut integer iacuit in polymer superficiem agens in obice.

- Exempla: Polysiloxanes.

- Pros: Bonum scelerisque stabilitatem, humilis fumus, non-halogenated.

- Cons: Potest esse magis pretiosa, specifica applications.

-

Intumescent flamma retardant systems:

- Mechanism: A compositum de acidum fons, carbonific agens et flante agente. In calefactio, formant densissima, spumida, carbonaceous integer iacuit quod insulat subjectis polymer.

- Exempla: Ammonium polyphosphate (Acidum Source) Pentaeythritol (carbonific agente), melamine (flante agente).

- Pros: Efficens, non-halogenated, humilis fumus et toxicus Gas productionem.

- Cons: Potest esse sensitivo ad humorem, ut afficit diaphanum, et exigit formula.

Applications de flamma retardant masterbatches

Flamma retardant masterbatbatches sunt necessaria in ingens ordinata applications ubi ignis salus est Paramunt:

- Aedificium et constructione: Cables et filis, tibiae, velit materiae, tecto membranas, muro tegumenta, Tabulatum.

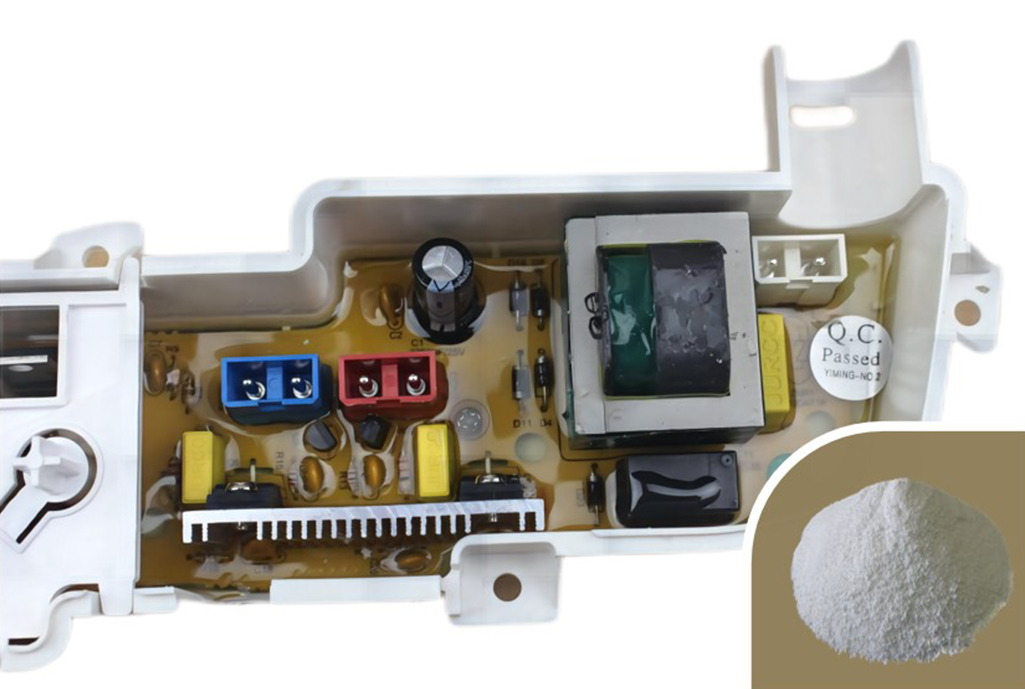

- Electronics et Electrical: Casings pro adjumenta, iungo, circuitu tabula components, filum et funem Jacketing, plugs.

- Automotive: Interior components (sedes, Dashboards, Porta tabulata), sub-the-hood applications, funem in tecta.

- Textiles: Upholstery, pelles, tutela indumentis, non-textilia.

- Translationem: Aircraft interiora, agmine components, marine applications.

- Furniture: Spuma, textilia, structural components.

- Packaging: Specialized tutela packaging.

Regulatory landscape et industria trends

Regulatory environment pro flamma retardants constantly evolving, repulsi augendae conscientia environmental et sanitas impingit. Key trends includit:

- Shift in non-halogenated solutions: Stricte ordinationes (E.G., Rohs, Weee, semoto) et crescente dolor demanda sunt propellentibus industries a halogenated flamma retardants versus magis environmentally benignum.

- Focus in humilis fumus et toxicity: Quam flamma propagationem, generatio fumi et toxicus vapores per ignem est a major est de humano salutem. Hoc ducitur ad maiorem extolleretur in flamma retardant systems ut minimize his byproducts.

- Euismod-fundatur signa: Rogations sunt magis magisque movere ad perficientur-fundatur signa (E.G., UL XCIV, en (XLV) DXLV ad Railway applications, variis aedificium codes) quam in flammate retardat, permittens pro innovation in flammam retardat formulas.

- Synergistic Systems: Formulators sunt magis developing synergistic combinationes de diversis flamma retardants ad consequi desideravit ignem perficientur ad minus altiore loading gradus et optimize cost-efficaciam.

- Sustainable Solutions: Research et progressionem sunt focused in bio-fundatur flamma retardants et magis sustineri vestibulum processus pro his additives.

Challenges et futurum Outlook

Quamvis significant progressiones, challenges manent in flamma retardant masterbatch industria:

- Balancing perficientur et proprietatibus: Achieving princeps flamma retardancy sine compromising mechanica proprietatibus, AESTHETICA, aut processability de Polymer manet continua provocatione.

- Cost-efficaciam: Developing effective non-halogenated solutions quae sunt oeconomica viable pro massa productio.

- Migratio et Leaching: Differit diu terminus stabilitatem flammae retardantibus in polymer vulvam et ne in migrationem vel leaching, praesertim in sensitivo applications.

- Recyclability: Designing flammae retardant systems, qui non impediat recyclability of polymer materiae.

Future de flammae retardant masterbatches erit characterised per continua innovation in non-halogenated chemistries, amplificata synergistic formulae et fortius emphasis in sustainable et circularis oeconomia principiis. Ut industries nituntur tutius products et magis sustineri futura, flamma retardant masterbatches et dubio manet in angularem in ensuring ignis salutem per ingens landscape polymer materiae.